Temperature Data Loggers: Optimizing the Monitoring of Pharmaceutical Products

In the pharmaceutical industry, the data logger, or temperature data logger, is a critical tool for ensuring the safety of temperature-sensitive healthcare products throughout their transport and storage. These devices precisely track temperature and humidity fluctuations, preventing the degradation of the quality of medicines or vaccines, which can be highly sensitive to environmental changes. The temperature data logger ensures that products remain within optimal temperature ranges and meet the stringent regulatory requirements for cold chain monitoring.

The Evolution of Temperature Data Loggers: From Mechanical to Digital

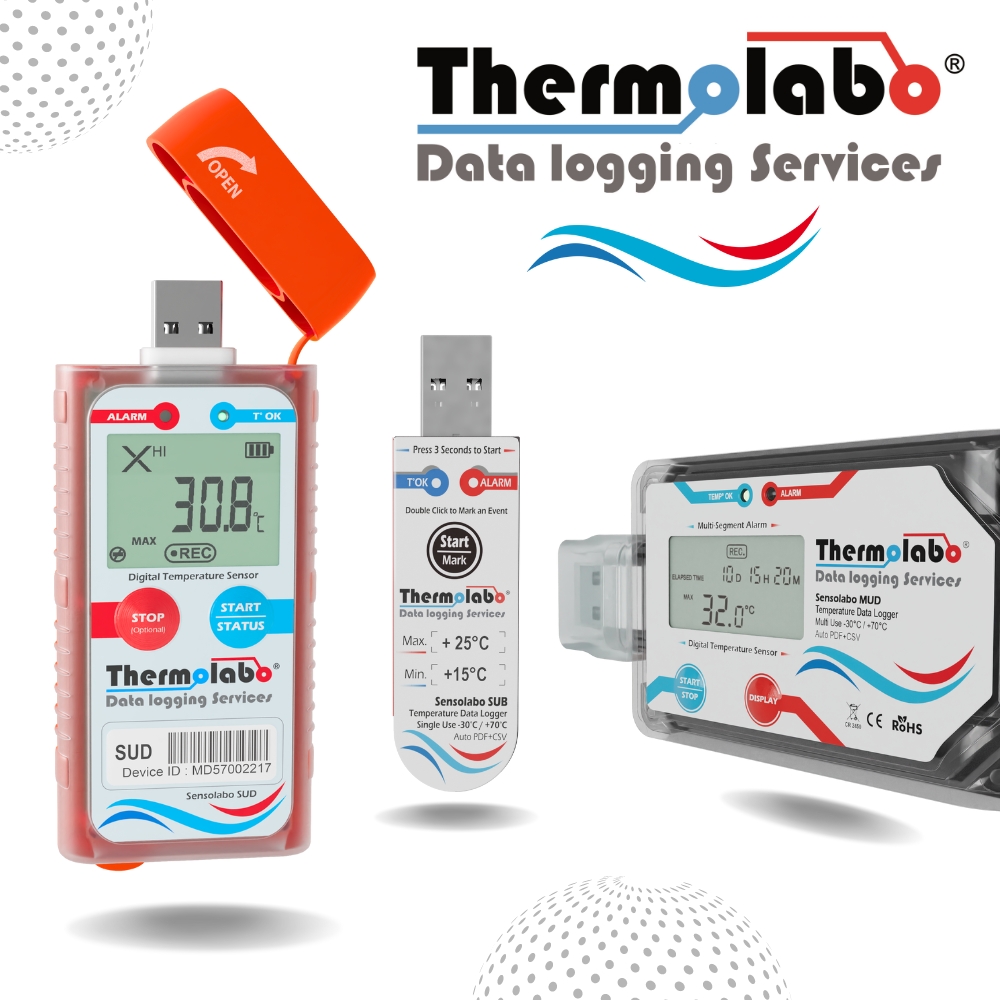

Once purely mechanical and often limited in functionality, temperature data loggers have now evolved into sophisticated, electronic, autonomous, and programmable devices. These new models can record data for periods ranging from a few hours to several months, depending on the specific needs of the user. For example, products like the Sensolabo SUD, a temperature data logger with USB connectivity, can continuously monitor temperature during transport or storage. This technology allows for the recording and storage of detailed information over long periods without requiring human intervention.

In addition to monitoring temperature, some data loggers can now also measure relative humidity, another critical factor in preserving the integrity of temperature-sensitive products. These devices ensure that healthcare products have not been compromised due to non-compliant temperature or humidity conditions during transport and storage. For instance, the Sensolabo SUD generates an automatic, detailed PDF report as soon as it is connected to a PC via a simple USB connection, simplifying the monitoring process and verifying storage conditions.

Why Managing Temperature Data Loggers Is Crucial

Managing data loggers in the pharmaceutical industry is complex, especially given the wide variety of models and brands available. While most data loggers require a connection to a computer to extract the data, the lack of common standards further complicates the management of these devices. Users are often faced with a multitude of data logger types, each requiring specific cables or software, which adds complexity to the process and increases the likelihood of human error.

Furthermore, low-cost models equipped with removable USB storage devices introduce additional risks. These devices can lead to data loss, file mismanagement, or technical failures, especially due to the poor quality of some models. It is therefore crucial to adopt high-quality data loggers that can withstand the demanding logistical conditions of the pharmaceutical industry. Managing these temperature data loggers becomes a significant logistical challenge: it is essential to integrate these devices into existing logistical data flows to avoid wasting time and resources. Proper management of these devices ensures that products under monitoring are never left without oversight.

Automation and Optimized Monitoring with NFC Technology

To address these challenges, automation of data collection and processing is essential. NFC (Near Field Communication) technology represents a major advancement in real-time monitoring of healthcare products. This contactless technology enables the instantaneous reading, sending, and storing of temperature data within just 2 seconds through a simple interaction between the data logger and a compatible device. This eliminates risks associated with human errors, improper cable connections, or the loss of traditional storage media.

Solutions like Sensolabo® NFC provide secure and fast management of temperature data, allowing the sender or logistics manager to be informed in a single action. The use of NFC technology also significantly reduces the time required for data processing. Information is stored and accessible in real time, enabling faster decision-making and more efficient management of alerts. This technology transforms the monitoring process for temperature-sensitive products into a smoother, faster, and more secure workflow.

Conclusion: The Importance of an Efficient and Connected Temperature Data Logger

In a context where logistical and regulatory requirements are becoming increasingly stringent, having reliable and high-performance temperature data loggers is indispensable. The connected temperature data logger has become a key tool in the pharmaceutical industry, enabling real-time monitoring of healthcare products throughout their supply chain. Thanks to technological innovations, modern temperature data loggers offer precise, reliable, and easily accessible monitoring data in real time. The automation of data collection and the use of contactless technologies, such as NFC, help eliminate human error and improve the efficiency of monitoring processes.

Advanced solutions combining USB connectivity and NFC technology ensure optimal management of temperature-sensitive products. They not only help meet regulatory requirements but also simplify and accelerate the management of data loggers. These technologies offer full visibility into storage and transport conditions, thereby ensuring product quality and safety. Digitalization and automation of monitoring processes are now key elements in maintaining an efficient, secure, and compliant pharmaceutical supply chain.

In conclusion, investing in an intelligent, connected data logger, such as those equipped with advanced technologies like NFC, is a strategic choice for optimizing the management of temperature-sensitive products. This system guarantees not only high-quality monitoring but also increased operational efficiency, simplifying logistics tasks and ensuring the safety of healthcare products throughout their journey.

Write a Comment